IJsselmeer - Netherlands

Oone of the first sailing trips with the new mithrandir (HAVCAT 31 build nr2)

Sweden - near Karlshamm

Mithrandir at the swedish south coast near karlskamm

RMY yard - RDM - Amsterdam

Simon Rhebergen, builder of multihulls with his first project building mould for serial production

RMY yard - RDM - Amsterdam

The process : build a exact copy of the boat in wood (plug), seal it with a smooth coat

RMY yard - RDM - Amsterdam

over the plug ( hull and deck here) one builds a stiff and strong female mould

RMY yard - RDM - Amsterdam

the female mould is pulled from the plug and ready to produce GRP parts from

RMY yard - RDM - Amsterdam

the surface of the mould is treated with a wax so the GRP part will not stick to the mould

RMY yard - RDM - Amsterdam

the outer layer of the GRP deckt (with the smooth outerskin still in the mould) before a foam layer is applied

RMY yard - RDM - Amsterdam

preparing glass fabric and foam to glue on the GRP part still in the mould.

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

after the foam is gue inside the GRP deckpart, the surface is smoothed and extra layers of glass are applied

RMY yard - RDM - Amsterdam

removing a GRP part from its mould

RMY yard - RDM - Amsterdam

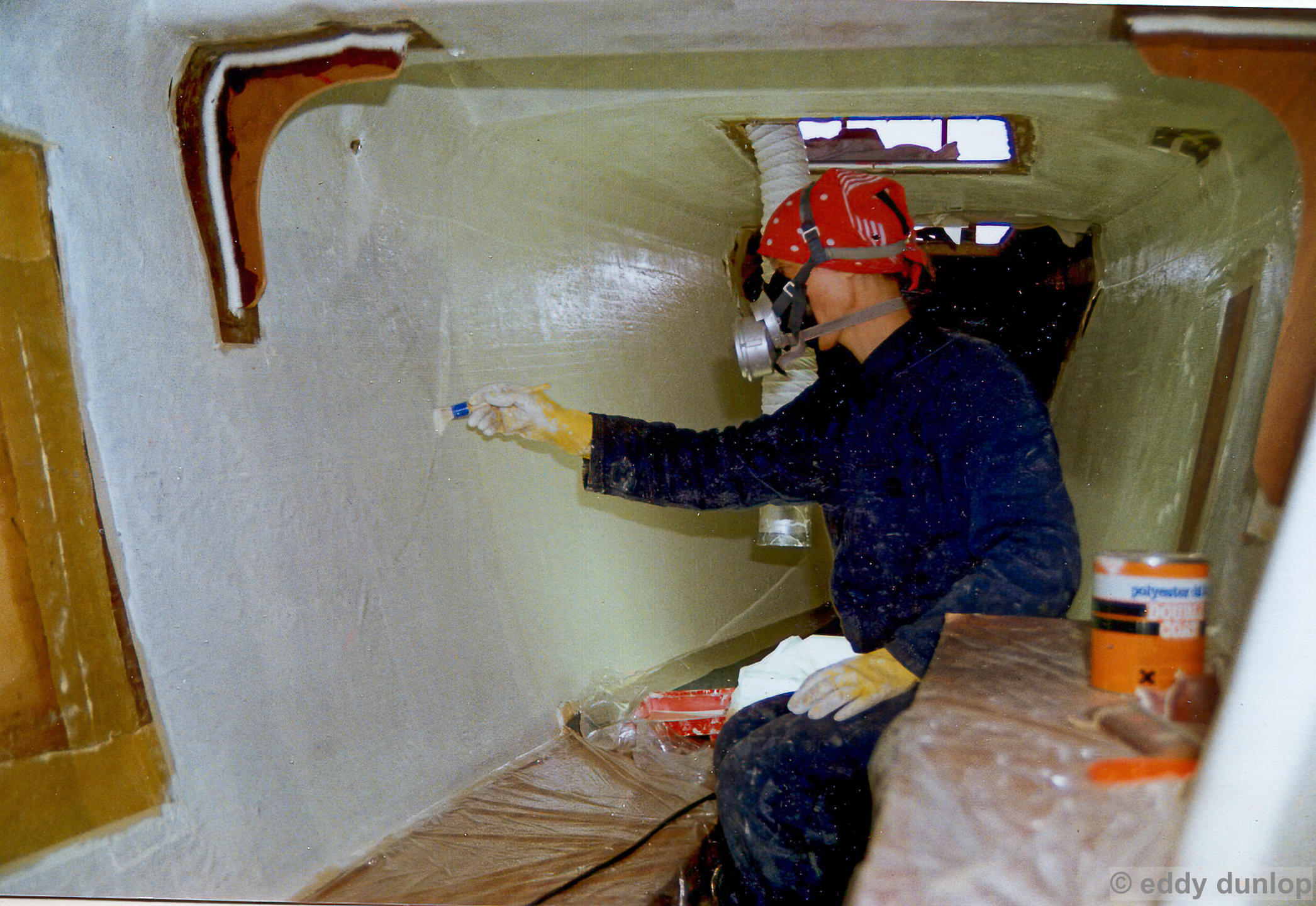

Eddy Dunlop on its own way involved in the building process

RMY yard - RDM - Amsterdam

applying foam on the first layer of the middle deck

RMY yard - RDM - Amsterdam

the first hull and deck are glued together (dec 1988)

RMY yard - RDM - Amsterdam

inside the deck and hull connection is reenforced with glass

RMY yard - RDM - Amsterdam

the bow up to the waterline is strengthend with kevlar to give extra protection against hitting floating objects

RMY yard - RDM - Amsterdam

this will become our next boat, how much work still?

RMY yard - RDM - Amsterdam

a hole is cut to install the daggerboard case inside in the hull

RMY yard - RDM - Amsterdam

a hole will be cut here to glue the daggerboard case inside the hull

RMY yard - RDM - Amsterdam

the case is mounted, the daggerboard enters from outside above and stick below the hull in the water

RMY yard - RDM - Amsterdam

waxing and polishing a mould

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

our first hull is ready to install the interior (to our own design)

RMY yard - RDM - Amsterdam

many more coffee needed before finishing all

RMY yard - RDM - Amsterdam

the plug of the middle beam, a very strong and complicated part. the mast will exert a enourmous compresion on the construction

RMY yard - RDM - Amsterdam

the plug of the middle beam is painted and ready to make the female mould from

RMY yard - RDM - Amsterdam

the upper and lower mould from the middle beam

RMY yard - RDM - Amsterdam

again, the first layers of glass in the mould of the middle beam

RMY yard - RDM - Amsterdam

the middle beam has a complicated construction inside

RMY yard - RDM - Amsterdam

the upper and lower part of the middle beam are glued together (still in the lower mould)

RMY yard - RDM - Amsterdam

the comleted middlebeam is lifted out of the lower mold

RMY yard - RDM - Amsterdam

parts of the interior arrive. we made them in our living room

RMY yard - RDM - Amsterdam

the beginning

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

finishing off the interiour

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

the frame of the escape hatch. what did I know that I had to use ir some years later

RMY yard - RDM - Amsterdam

mithrandir starts looking like a boat. But still a lot of work to do.its begin of april, launch in begin of may !!

RMY yard - RDM - Amsterdam

discussing how to cut a hole for a window

RMY yard - RDM - Amsterdam

relaxing

RMY yard - RDM - Amsterdam

beautiful all this mahogany

RMY yard - RDM - Amsterdam

many friends lend a hand

RMY yard - RDM - Amsterdam

the aft trampoline is ready. willem made it

RMY yard - RDM - Amsterdam

the trampoline is checked for size

RMY yard - RDM - Amsterdam

the last plug, for the outboard mount, is made

RMY yard - RDM - Amsterdam

and the female mould of the outboard mount is ready

RMY yard - RDM - Amsterdam

removing the plug from the mould is not easy

RMY yard - RDM - Amsterdam

thatsv it, the ultimate mould for the Havcat 31 is finished

RMY yard - RDM - Amsterdam

sleeping during thev work shift, it is allowed

RMY yard - RDM - Amsterdam

family is admiring our work

RMY yard - RDM - Amsterdam

the boat is outside. within a week she will be launched. the mastmaker is there to install the mast

RMY yard - RDM - Amsterdam

this one looks to tall

RMY yard - RDM - Amsterdam

installing the windex wind direction pointer

RMY yard - RDM - Amsterdam

view from above

RMY yard - RDM - Amsterdam

the boat does not look finished, however the guest are already invited for the launch.

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

the day before the launch

RMY yard - RDM - Amsterdam

willem at work

RMY yard - RDM - Amsterdam

gerrit and many more friends help at the last day before launch

RMY yard - RDM - Amsterdam

what were we young and relaxed

RMY yard - RDM - Amsterdam

the day of the launch, our regular crane driver is available in time

RMY yard - RDM - Amsterdam

I am lifted and feel lucky

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

I baptize you "mithrandir", the elves name of gandalf from tolkien's Lord of the Rings

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

RMY yard - RDM - Amsterdam

build nr 3, definitely

RMY yard - RDM - Amsterdam

first trip with mithrandir

checking if all the bolds are fixed okay

lifting a hull

fast she is, definitely !!!

complicated, those lines

a swedish friend, ib moller, wrote an article for a watersports magazine after we met in sweden

history